-The worm gear backlash can be adjusted to less than 1 arc minute

-The meshing gap can be readjusted after the reducer is used

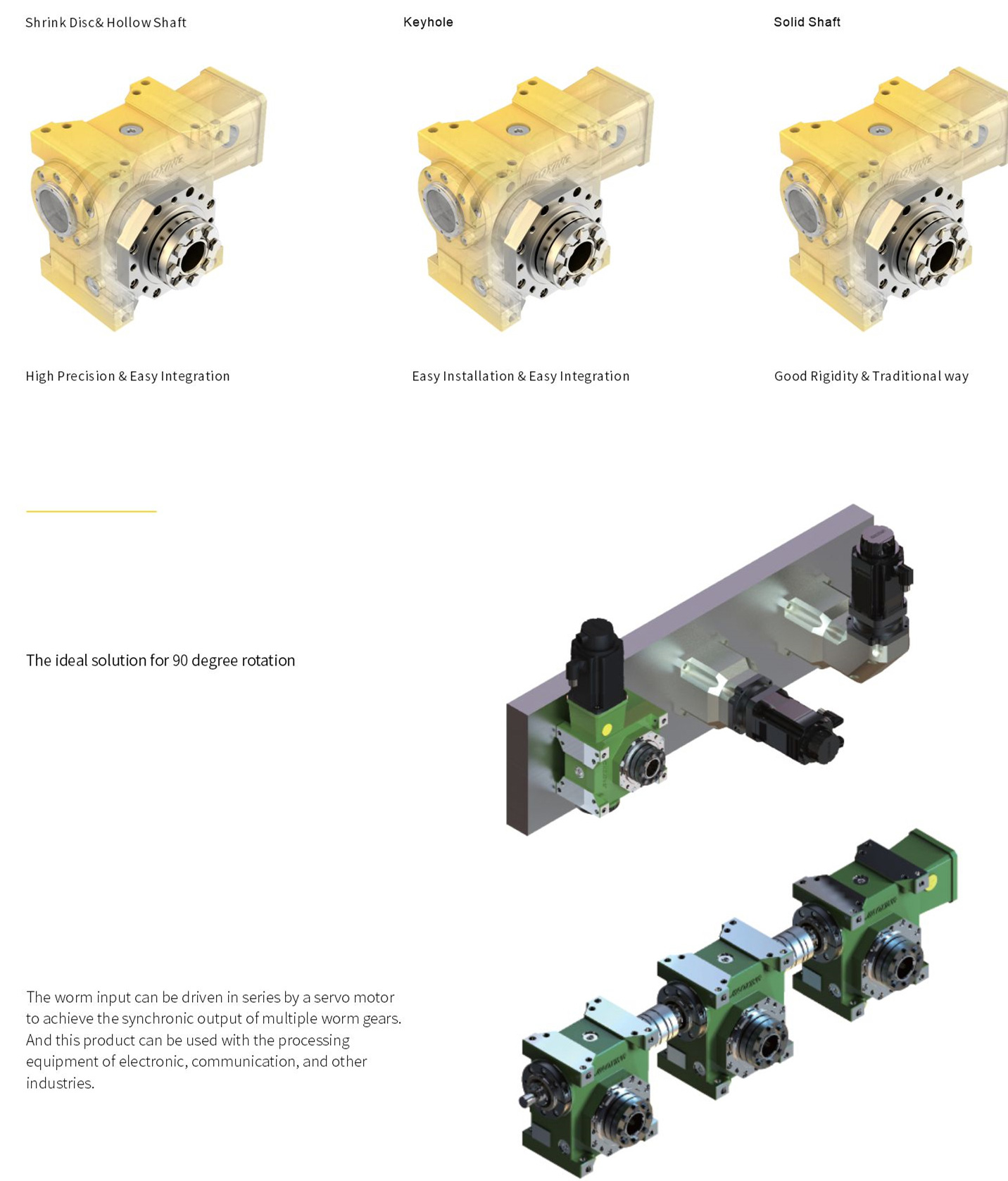

-The shaft coupling is used for the input: reliable and no backlash

-The tapered clamping ring coupling is used for output: reliable and backlash-free

-Worm gear gyration backlash can be adjusted to less than 1 arc。

-Reducer can be re-adjusted the gap after using。

-Inpul with coupling reliable without backlash。

-Output using conical clamping nng couplings: reliable without backlash。

*The Advanced processing technology and precise assembly ensure the gear teeth properly mesh and the reduction of contact stress

*The specially developed copper alloy worm gears make the gear teeth have high strength and wear resistance

*The high-ratio contact of gear teeth assures the worm gear is not easy to wear and can keep the backlash lock for a long time

*The Lubricating oil is high-performance fully synthetic

*Fully enclosed structure& no need to change the lubricating oil

* The backlash can be quickly set

* Good rigidity& High precision

* Patent structure design

* High-rigidity and low-inertia shaft couplings for servo motors

* Various flanges mathced with servo motors

* Can withstand large axial loads

* Bearing preload installation provides higher rigidity support

* Two tapered roller bearings mounted on one end for longer endurance

* Eliminate errors caused by thermal elongation of the worm

* Bearing preload installation provides higher rigidity support

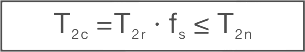

* Super precision: 1 arc minute for the high requirement occasion

* Precision: 2~4 arc minutes for the compromise between quality and price

* It is cast from high strength aluminum alloy and then heat-treated

* Strong Rigidity&Light Weight

* Beautiful appearance and strong weather resistance

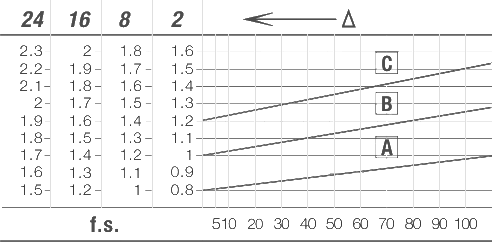

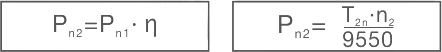

1.Load Classification:A-B-C

2. Running times: hours/day)

3.Boot frequency: times/hour

A:Balanced load

B:Moderate shock load

C:Heavy-duty load

fa=Je/Jm

Je(kgm²): Moment of Inertia decaying on the drive shaft

Jm(kgm²): Motor Inertia

If fa>10, please contact the technical service department系

A-Lightweight Screw Conveyor, Fan, Assembly Line, Lightweight Belt Conveyor, Small Mixer, Hoist, Cleaning Machine, Filling Machine, Controller。

B-winding device, woodworking machinery, cargo hoist, balancer, screw machine, substrate mixer, belt conveyors for heavy material, winch, automatic sliding door, scraper conveyor, packaging machine, concrete mixer, crane, grinding machine, coils machine, gear pump。

C-heavy material mixer, shearing machine, press machine, centrifuge, rotating support, heavy material winch and hoist, grinding machin, stone, elevator, drilling machine, hammer mill, cam press, folding machine, Conveyor belt, dump truck, vibrator, shredder