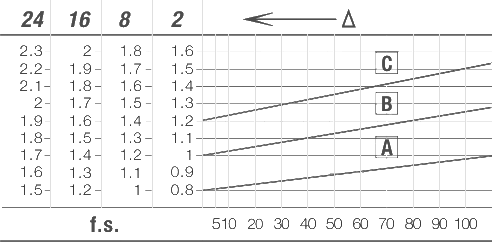

1.Load Classification: A: Balanced load

B: Moderate shock load

C: Heavy-duty load

2.Running times: hours/day

3.Boot frequency: times/hour

Je(kgm²): Moment of Inertia decaying on the drive shaft

Jm(kgm²): Motor Inertia

If fa>10, please contact the technical service department

A-Lightweight Screw Conveyor, Fan, Assembly Line, Lightweight Belt Conveyor, Small Mixer, Hoist, Cleaning Machine, Filling Machine, Controller.

B-winding device, woodworking machinery, cargo hoist, balancer, screw machine, substrate mixer, belt conveyors for heavy material, winch, automatic sliding door, scraper conveyor, packaging machine, concrete mixer, crane, grinding machine, coils machine, gear pump.

C-heavy material mixer, shearing machine, press machine, centrifuge, rotating support, heavy material winch and hoist, grinding machin, stone, elevator, drilling machine, hammer mill, cam press, folding machine, Conveyor belt, dump truck, vibrator, shredder