1、Exquisite construction, Light weight, Superior strength

2、The Small Size can effectively improve the heat dissipation performance

3、Compact installation space, high transmission torque and overload capacity

4、High endurance for harsh environments, stable operation, low noise, self-locking function

1.Must be installed stably on the machine without any loosening

2.Before installing the reducer, checking the rotational direction of the output shaft of the reducer is a requirement

3.In the case of long-term storage (4-6 months), once the oil seal is not immersing in the lubricating oil of the reducer, the rubber may stick to the main shaft or even lose its elasticity. Since elasticity is a requirement for a good oil seal, the recommendation is to replace it

4.In the case of long-term storage (4-6 months), once the oil seal is not immersing in the lubricating oil of the reducer, the rubber may stick to the main shaft or even lose its elasticity. Since elasticity is a requirement for a good oil seal, the recommendation is to replace it

5.Must Avoid the reducer from direct sunlight or exposure to the harsh climate

6.Must make sure the good airflow around the motor fan for the adequate cooling

7.If the absolute temperature of the reducer when using it is less than 5 Celsius or higher than 40 Celsius, contact our technical staff

8.The parts, such as pulleys, gears, couplings, and shafts, must be installed on solid or hollow shafts, and the specialized threaded holes or other tools are required to ensure the installation will not damage the bearings or all parts on the outer end. In addition to that, the lubrication of the contact surface is necessary to avoid sticking or oxidation

9.Rubber parts and air vents must not be covered with paint

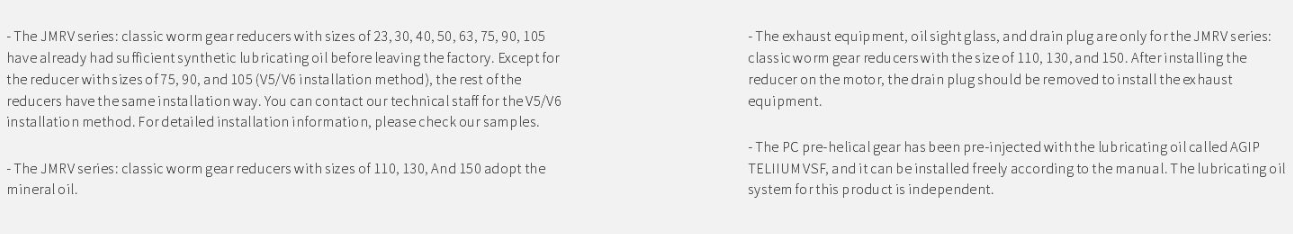

10. When purchasing a reducer with an oil plug, please remove the special plug for transportation and install the exhaust plug

11.The oil sight glass has the function of checking whether the amount of lubricating oil is enough or not

12.The load of the new reducer should increase gradually, instead of raising up to the maximum load immediately

13. If there are any parts, objects, or materials that can leak the oil next to the reducer, then that reducer will need special protection or shielding to avoid damage from the external factors

1.Please refer to the relevant standard to check whether the shaft and flange of the motor have excessive errors during installation。

2.Please carefully clean the dirt and dust on surfaces of the shaft, coupling, and flange

3.Please install the shaft carefully to ensure the shaft and hole tolerance fits. In addition to that, please avoid the damage caused by excessive force during installation. If it is necessary, use the specialized tools.

4.Remove glitches ( the position and deviation of the motor keyway should be within the specified range)。

5. Lubricate the contact surfaces with lubricating oil to avoid seizing or oxidation。

1.The CVT is not for the situations where overload or stall may occur。

2.The adjustment is allowed during the operation, and it is strictly forbidden to turn the adjustment handwheel when the CVT stops operating。

3.The limit screws at both ends under the operation box have been adjusted. Please do not move。

4.The product should not operate in an environment with a temperature higher than 40°C, and the temperature rise should not be higher than 50°C。

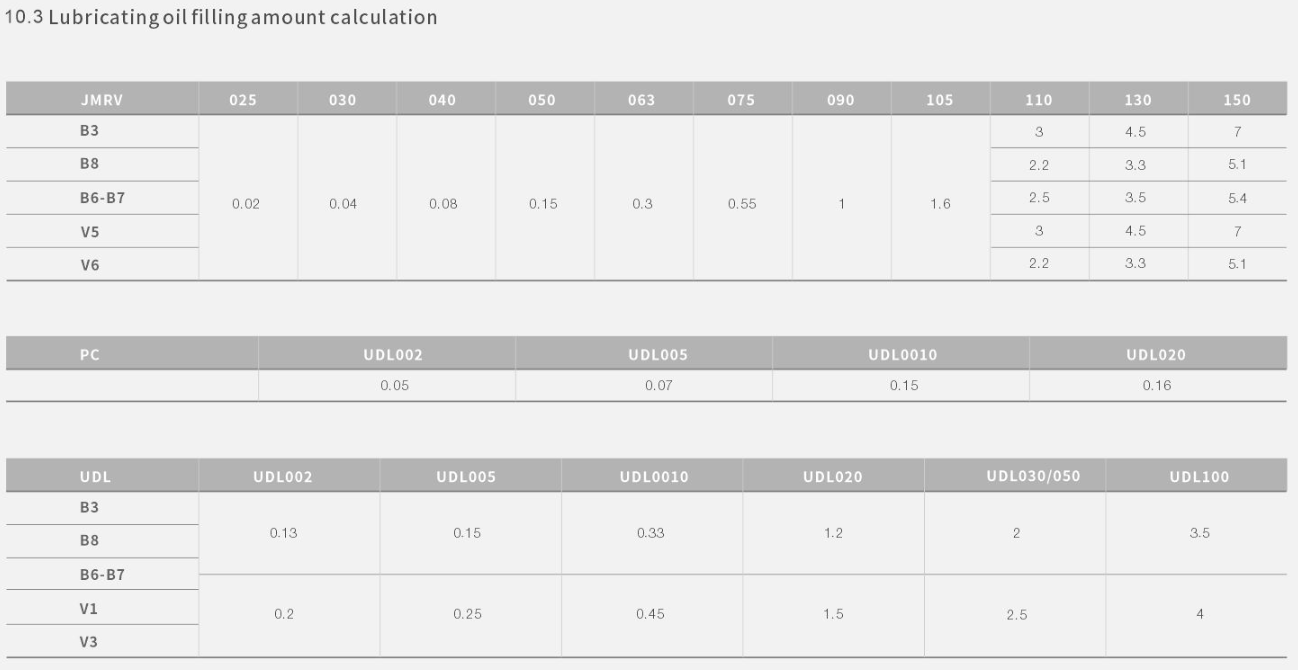

5.The product has already had sufficient lubricating oil before leaving the factory, and the first-time replacement of the lubricating oil should be after the use of 1000 hours. Then every 5000 hours once.

6.The lubricating oil in the product should always be two-thirds of the oil level. And the user should check the oil level frequently since it is strictly forbidden to operate in the case of poor lubrication。

7.The vent nut on the operation box has been tightened to prevent oil leakage during transportation, and it must be loosened during operation.

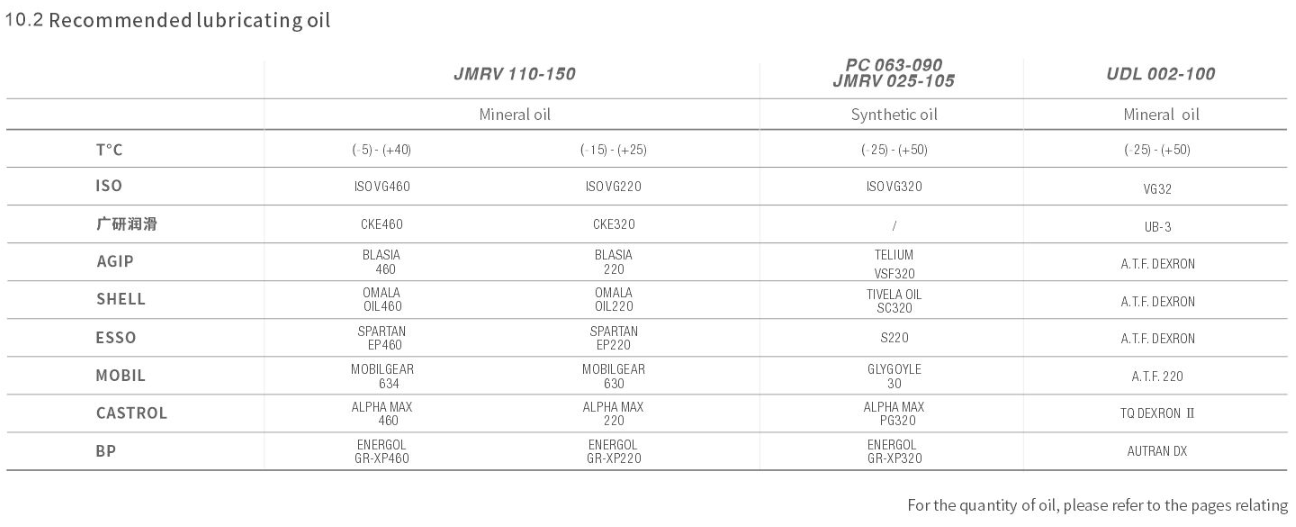

If you cannot find the corresponding temperature in the table, please contact with our technical staffs

If the temperaturee is lower than -30 ℃, or higher than 60 ℃,the specialized oil seal is required

If the temperature during oil filling is lower than 0 ℃, the following points must be observed:

1.The selection of the motor must conform to the surrounding environment and working conditions。

2. The starting torque in cold weather is the significant factor for selecting the power of the motor。

3.The Reducer with a cast iron gearbox should avoid the sudden heavy shock load, as the cast iron may become brittle at -15°C or below。

4.At the beginning of use, there might be a problem related to the lubricating oil since the viscosity of the new lubricating oil is relatively high. As a result, operating the reducer for a few minutes under the no-load condition before starting to load is recommended. The replacement of the lubricating oil should be after the first-time use of 10,000 hours, but it also depends on the specific working environment. As for the reducer without the oil fill hole, there is no need to change the lubricating oil。